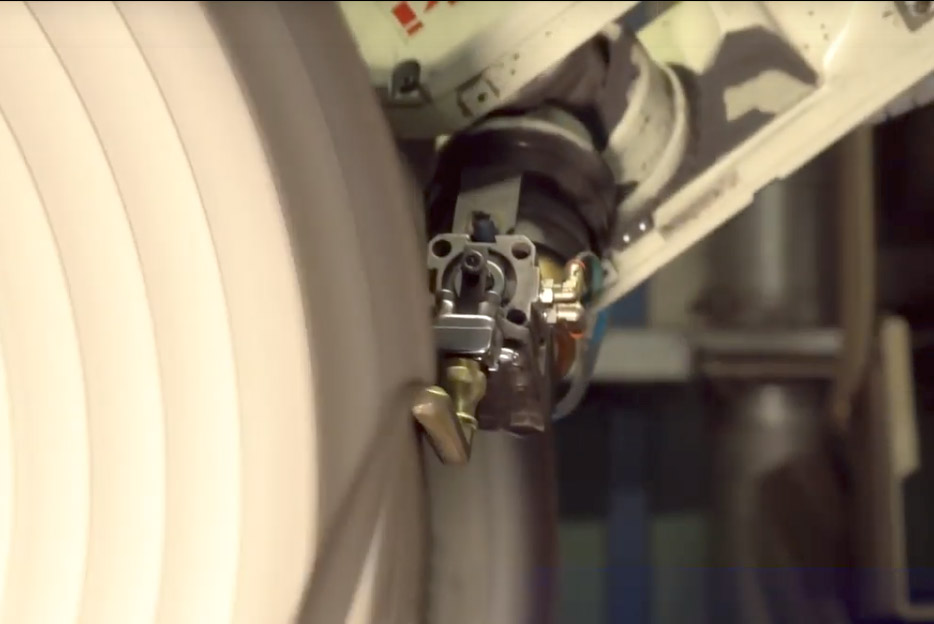

Grinding, bronze and washing department

- MQ 1.800

- Specialized department in manual and robotic grinding

- Possibility to work different materials

- Realization of bronzed finishing with a fully automated implant

- New-generation vacuum washing implant connected to the company’s control and management system

- 0 environmental impact

High Coat department

- MQ 1.500

- Fully automated department

- Management of galvanizing tanks and cataphoresis coating using new-generation software

- Quality control during the loading and unloading process of products

- A polymerization oven, which allows to give technical and aesthetic characteristics of hardness, transparency and brilliant to the coat

- Internal laboratory for treatment analysis and plant monitoring

- Daily measurements of the levels of hardness, grip and thickness of the paint

- Machine for corrosion tests, cass-test

Assembling, packaging and CNC

- MQ 3.000

- 7 robotic islands for automatic assembly

- 10 packaging lines

- Conveyor belt for automatic supply of master carton to the lines

- Automatic palletizer for autonomous management of 12 orders simultaneously

- Various equipment for mechanical processing

- CNC active 24/7 to create prototypes of any material